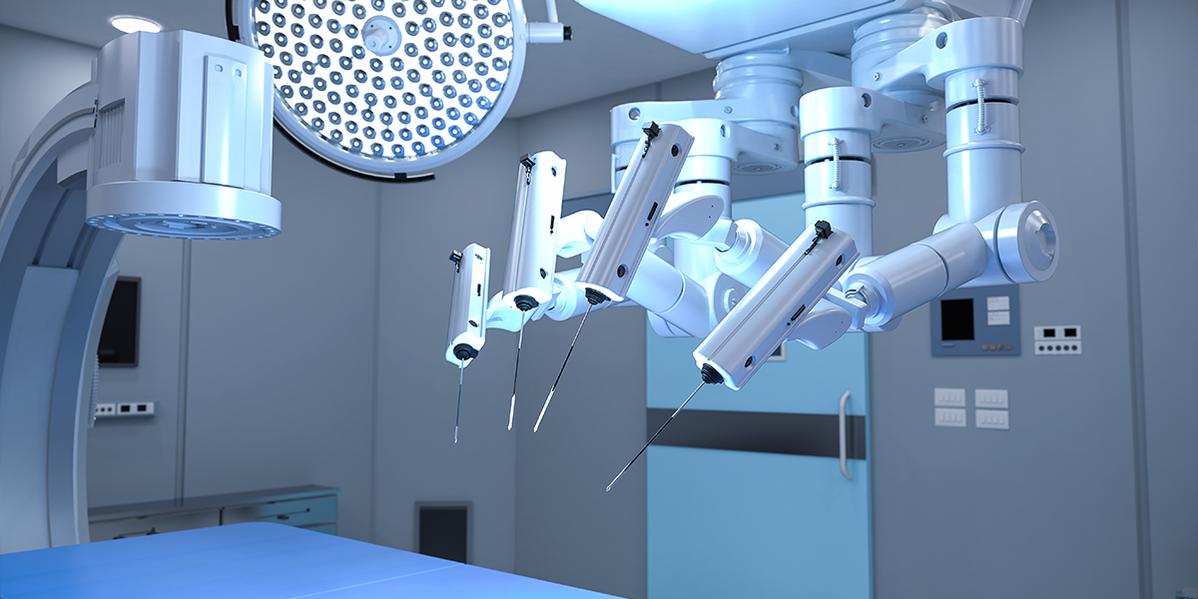

Robotic-assisted surgery (RAS) is an emerging field that combines robotic technology with surgical precision. While fully automated surgical robots are still under development, RAS systems, where surgeons control robotic arms from a console, are becoming more common. These systems offer significant benefits, including increased precision, faster surgeries, and shorter recoveries, which enhance patient care and reduce overall costs. However, RAS also presents challenges including high initial costs, extensive training requirements, and complex technology integration. Fortunately, solutions and strategies exist to overcome these challenges.

The High Costs of Robotic-Assisted Surgery

RAS is by no means a low-cost investment, with the initial investment running into the millions. For instance, the da Vince Surgical System costs around $2 million initially, not including staff and surgeon training as well as maintenance and surgical accessories.

Not to mention the supplementary equipment such as imaging system, specialized surgical tools, and the infrastructure needed to house the surgical suite. The size is typically required for RAS is approximately 600-700 square feet.

Maintenance and Operating Costs

According to Surgical Robotics Technology, the annual maintenance fees and operating costs for RAS can be substantial, roughly ranging from $100,000 to $200,000 each year. While these costs can be recouped through shorter recovery times and improved patient outcomes, they can sometimes be higher than expected, making RAS unaffordable for some healthcare facilities.

A significant part of the operating costs includes disposable instruments and parts. For example, surgical items like single-use scissors and forceps, which can cost between $700 and $3,500 per procedure.

Cost-Benefit Analysis

Yet, despite the initial high cost of state-of-the-art RAS systems, the long-term savings due to reduced hospital stays and improved outcomes may make the cost lower over time. In one study conducted by Johns Hopkins Medicine, it was shown that RAS reduced the total cost of ownership (TCO) by 20% within three years. Robotic surgeries have also been shown to reduce the total hospital stay for prostatectomy procedures by 1-2 days, resulting in a cost savings of approximately $1,500 to $2,000 per patient.

Examples of Cost-Effective Solutions and Strategies

- Implementing a leasing model for RAS equipment

- Utilizing refurbished systems and instruments

- Partnering with trusted technology providers for bundled services and maintenance plans

Kontron’s Solutions

Another way to reduce the costs of RAS is in the design phase. Kontron’s computer-on-modules (COMs) and motherboards can serve as the central processing units in robotic arms. COMs are scalable and flexible, making them ideal for easy upgrades without the need to replace the entire system. You can replace a module with a new one without redesigning the whole system, which significantly lowers the TCO.

Kontron's solutions provide robust, reliable, and long-term support for various applications, ensuring high performance and adaptability to future advancements. Additionally, these modules support multiple I/O interfaces, enabling seamless integration with other systems and facilitating upgrades to maintain cutting-edge functionality.

Link: https://www.kontron.com/white-paper-the-future-of-surgery-is-here

Training and Skill Development for Surgeons

Robotic-assisted surgery requires intensive training to merge the surgeon's skills with machine technology. Surgeons utilize AI, machine learning, haptic feedback, and 3D visualization to control robotic arms. Programs like Intuitive Surgical’s da Vinci training include online modules, hands-on practice, and proctored cases. Simulation-based training with virtual reality (VR) is also crucial. Despite the steep learning curve, effective training enhances precision and reduces operative times, addressing significant safety concerns.

Continuous Education

After initial training surgeons and nurses need ongoing training and skill refinement. Here are few training programs available:

- Advanced Robotics Training by SAGES (Society of American Gastrointestinal and Endoscopic Surgeons: This program offers specialized training in robotic-assisted gastrointestinal and endoscopy surgery.

- Online modules and webinars by the American College of Surgeons (ACS): Keeps surgeons updated on the latest advancements in robotic surgery.

- Workshops by experienced RAS surgeons: These workshops provide practical, hands-on experience with robotic systems.

Kontron’s contribution to training technologies such as realistic stimulators powered by their high-performance modules helps prepare surgeons for RAS. COM-HPC modules with their increased performance and visual capabilities aid technologies like haptic feedback.

These modules provide enhanced processing power, superior graphics support, and high data transfer rates. Features like multiple PCIe lanes, USB4 support, and advanced Ethernet interfaces ensure smooth and responsive feedback. This enhances tactile sensitivity and responsiveness, allowing surgeons to feel firmness or touch through vibrations, making the training process more realistic and effective.

Technology Integration and Interoperability

Like all technological achievements, RAS integration with existing IT infrastructure comes with challenges.

Challenges in Integration

Data interoperability can be difficult because different systems may not communicate effectively with each other, leading to fragmented data. Another concern has to do with system compatibility, which can cause delays or errors during surgery. Additionally, cybersecurity is a significant concern, as patient records and data must be kept private during and after surgery.

Standardization and Compliance

Integrating RAS also means strict adherence to medical standards and regulations. For example, the IEC 60601-1 standard ensures the safety and performance of medical electrical equipment. The role of standardization in ensuring seamless integration benefits both patients and healthcare providers by ensuring consistent and reliable performance.

Interoperability Solutions

There are different ways to achieve seamless data exchange and system interoperability, including:

- Implementing Health Level Seven (HL7) standards.

- Using Application Programming Interfaces (APIs) for seamless data flow.

- Integrating electronic health records (EHR) with RAS systems.

- Using these methods can streamline operations and ensure efficient data management. Here are some successful examples of integration projects:

- The Mayo Clinic’s integration of RAS with their EHR system

- Cleveland Clinic’s use of APIs for data interoperability in their surgical suites =

Kontron’s interoperable COM modules are compliant with medical standards because they adhere to rigorous testing and certification processes. Additionally, SecureGuard® USB blockers and other security solutions help address cybersecurity challenges.

Case Studies and Success Stories

A Fortune 500 manufacturer approached Kontron looking for a partnership in developing a RAS suite for multiple procedures. Kontron was chosen for its world-class quality, brand reputation, and being a trusted adviser. Additionally, the partner needed to have ISO 13485 certification and provide excellent customer service. In addition to these fundamental requirements, the OEM needed the following three criteria, which Kontron had:

Design in Scalability

To create flexible and scalable RAS systems, Kontron’s computer-on-modules (COMs) provide the processing power and flexibility needed for varied applications. This modular approach allows OEMs to develop products with different capabilities, such as more affordable robotic surgical devices for developing nations. Scalability ensures that modules can be replaced or upgraded without requiring a complete redesign, significantly lowering costs and allowing for tailored solutions to meet diverse market needs.

Achieve Rapid Time to Market

Kontron’s COMs help expedite the development process by minimizing noncore design time. By utilizing proven modules and processor technologies, OEMs can reduce both the time and costs associated with bringing new products to market. This is crucial in the fast-growing medical market where rapid innovation can provide a competitive edge and meet urgent healthcare needs.

Future-proof and Protect Intellectual Property (IP)

Futureproofing involves designing systems that can easily adapt to next-generation technologies. Kontron’s modules support this by allowing for seamless upgrades and integration with new advancements. Protecting intellectual property is equally important; Kontron’s solutions are designed to safeguard proprietary technologies, ensuring that OEMs can innovate confidently while maintaining competitive advantages and avoiding the high costs associated with frequent redesigns.

Key Takeaways

By 2032, the robotics market is expected to reach approximately $14 billion. OEMs need to be poised to take advantage of this growth by providing high-quality robotic suites that improve patient care. However, achieving this can be problematic due to several challenges:

- High Initial Costs: Developing a RAS system can run into millions of dollars, making it difficult for many healthcare facilities to afford the investment.

- Training Expenses: Significant costs are associated with training surgeons and ongoing maintenance, which can range from $100,000 to $200,000 annually.

- Public Trust: Gaining the public’s trust in robotic surgery is essential for widespread adoption.

Solutions to Overcome Challenges:

- Cost Efficiency: Implement leasing models, use refurbished systems, and modular systems for easy upgrades.

- Training and Precision: Invest in VR and simulation-based learning, ensure surgeons can achieve greater precision and improved outcomes.

- Building Trust: Promote successful robotic-assisted surgery use cases to encourage trust and accountability.

These strategies make RAS more accessible and maintain its position as a cutting-edge solution in modern surgical practices. The future of RAS is bright and just beginning. While robots may be assisting experts now, the future may be quite different, with robots completing entire surgeries without any tactile support from the surgeon. To learn more about these challenges, download our in-depth white paper “Beyond Science Fiction: Realizing the Potential of Robotic-Assisted Surgery.”

Learn More: Discover Kontron’s innovative products. Visit our product page.

Download Our Whitepaper: Realizing the Potential of a Robotic-Surgical Suite. Download Now.

{{comment.comment}}